What is the difference between OEM precision molds and ordinary molds

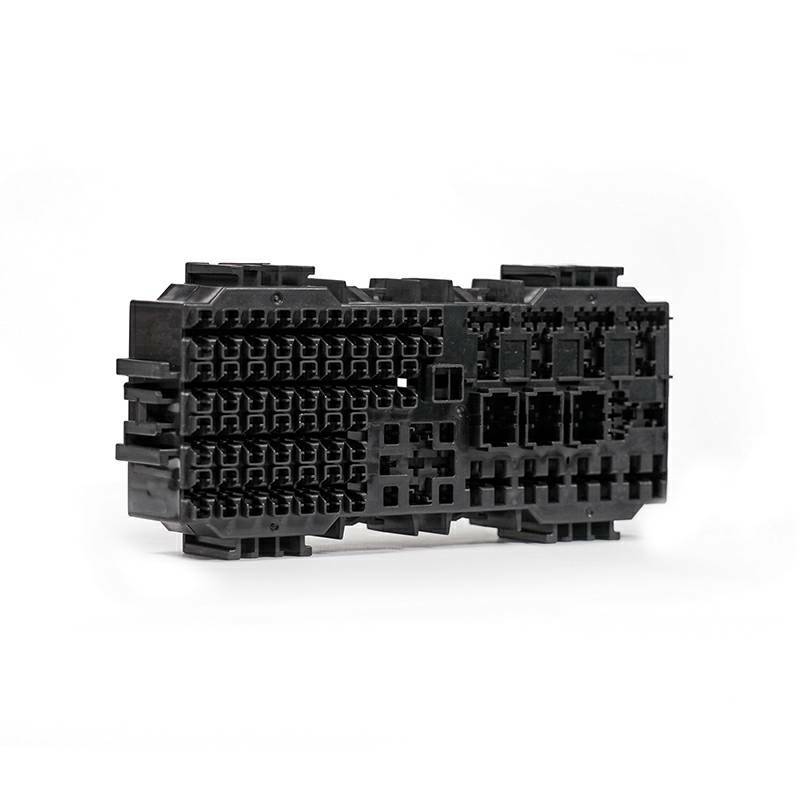

Now let's take a look at the six characteristics of OEM precision mold forming:

1.The product has high dimensional accuracy and small tolerances, that is, there are high-precision dimensional lines;

2.Is to require high product repeatability and stable dimensions by day, month and year;

3.The mold material is good, the rigidity is sufficient, the dimensional accuracy and smoothness of the cavity, and the positioning accuracy between the templates are high;

4.Replace conventional injection molding machines with precision injection molding machines;

5. Using precision molding technology;

6. Choose materials suitable for precision molding.

Many key dimensions of precision molds are not allowed to have an inclination, but when making the mold, the tolerance zone is generally used to increase a small inclination, such as gear mounting posts. Pay attention to the adjustment of tolerances when building a digital model. The 3D model provided by general customers is unreasonable, because many of its dimensions are extreme dimensions. If the mold is designed according to this, the manufactured mold will basically be scrapped.

Secondly,the drawings are required to be comprehensive and accurate, try to use inserts, consider processing, and try to use machines to ensure the size (the role of fitter technology in precision plastic molds is to strictly follow the drawings. Most mold parts should be accurately designed with tolerances, not only It is the working part of the cavity and core, and the dimensions related to the installation position of all inserts should be strictly limited. Generally controlled at +/-0.005.

.jpg)